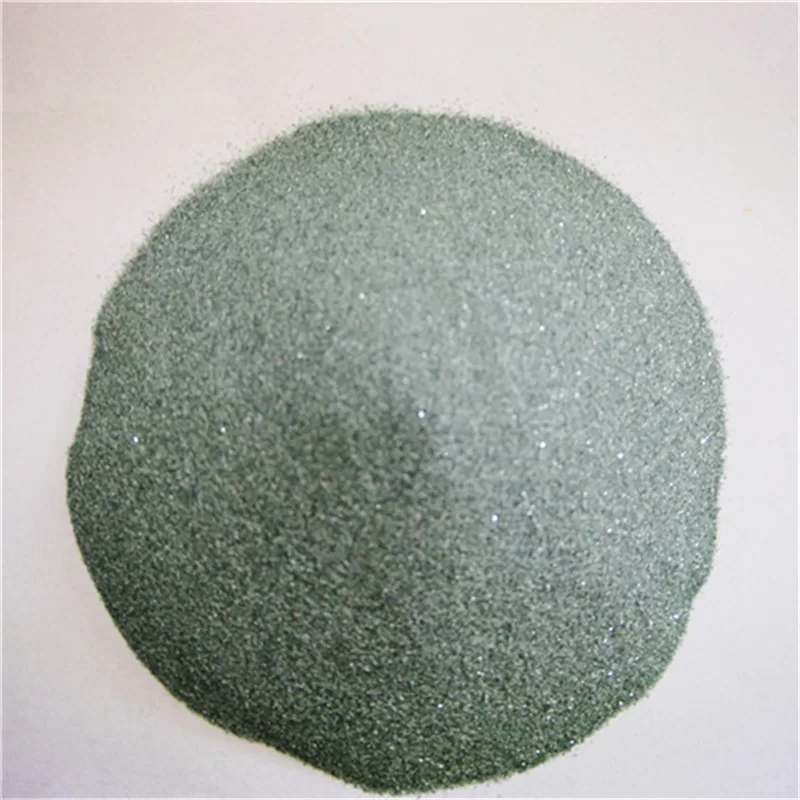

Green Silicon Carbide Granularity Sand

Green Silicon Carbide Granularity Sand

| Color | Green |

| Raw Material | Quartz Sand, Petroleum Coke (or Coal Coke), Sawdust |

| Crystal Structure | Hexagonal Crystal |

| True Density | 3.2 g/cm³ |

| Molecular Weight | 40.096 |

| Hardness (Mohs) | 9.5 |

| Melting Point | 2700°C |

| Particle Size | F Grit, P Grit, W Micro Powder, Segment Sand, Fine Powder |

| Applications | Refractory materials, abrasives, photovoltaic industry, semiconductor industry, piezoelectric crystals, and various other fields |

Introduction to green silicon carbide:

Green silicon carbide is a kind of silicon carbide, all belong to α-SiC, green silicon carbide contains more than 97% SiC. Green silicon carbide is petroleum coke and silica as the main raw material, add salt as an additive, in the resistance furnace by high temperature smelting. It is green crystalline, brittle and sharp, and has thermal and electrical conductivity. Its density is generally considered to be 3.20-3.25g/cm3. green silicon carbide’s natural packing density is between 1.2-1.6g/cm3, specific gravity is 3.20-3.25g/cm3. microscopic shape of hexagonal crystals, Moh’s hardness of 9.2, Nup hardness of 2670-2815kg/mm2, Vickers hardness of 3000-3300kg/mm2. The hardness is 9.2 on Moh’s scale, 2670-2815kg/mm2 on Nulp scale, 3000-3300kg/mm2 on Vickers scale, which is higher than corundum and second only to boron carbide, diamond and cubic boron nitride in abrasives.

| Test Products | SIC% | F.C% | Fe2O3% |

|---|---|---|---|

| Green silicon carbide 20#-90# | ≥99 | ≦0.20 | ≦0.20 |

| Green silicon carbide 100#-180# | ≥98.5 | ≦0.25 | ≦0.50 |

| Green silicon carbide 220#-240# | ≥98 | ≦0.25 | ≦0.70 |

Green silicon carbide prospects:

With the continuous progress of science and technology and industrial development, the demand for high-performance materials is increasing. As an excellent material, green silicon carbide has a broad application prospect. In new energy, electronic devices,, automotive manufacturing and other fields, the application of green silicon carbide will be further expanded. At the same time, with the improvement of the preparation process and technological innovation, the performance and application of green silicon carbide has a lot of room for development.

Green silicon carbide characteristics:

1, rust resistance: green silicon carbide has good resistance to acid, alkali and other corrosive media, and can operate stably for a long time in a corrosive environment.

2, high hardness: green silicon carbide has a high hardness, second only to diamond and boron nitride, can be used to make high hardness ceramic materials and abrasives.

3, high-temperature stability: green silicon carbide can maintain stable performance in high-temperature environments, with a long service life and reliability.

4, corrosion resistance: green silicon carbide on acid, alkali and other corrosive media with good resistance, can be in a corrosive environment for long-term stable operation.

5, high hardness and usability: green silicon carbide has high hardness and usability, can be used to make use, corrosion-resistant parts and tools.

6, heat-resistant temperature performance: green silicon carbide has ** heat-resistant temperature performance, can be maintained in a high-temperature environment to maintain stable performance, resistance to high-temperature thermal shock and thermal stress.

7, excellent thermal conductivity: green silicon carbide has good thermal conductivity, can be used to make heat sinks, heat conduction plate and other heat dissipation materials.

8, wide range of applications: green silicon carbide in electric power, machinery manufacturing, iron and steel metallurgy, chemical industry and many other industries and fields have a wide range of applications, to meet the requirements of different areas of material performance.

Green silicon carbide use areas:

1.Processing ceramic heat sink/ceramic filter/ceramic membrane

2. Coarse and fine grinding media for flat double-sided grinding and polishing machine.

3. For sand blasting and grinding of cemented carbide, metal grinding and polishing, and tombstone engraving.

4. Functional ceramics/functional ceramic stone/honeycomb ceramics/architectural ceramics

5.Bearing processing/bearing ultra-fine processing and grinding

6. Piping layer/engine layer

7. For high hardness silicon wafer cutting/wire cutting/photovoltaic wire cutting

8. For tool grinding and polishing High hardness steel tool grinding, grinding powder for single and double sided grinding.

9. Oil stone/grinding stone/sharpening stone/brush roll for production

10.Optical glass / stone polishing / marble polishing wheel / gemstone polishing / polishing disc polishing

11. Diamond tools / ink pads / dry grinding pads production of auxiliary materials

Packing:

- 25kg paper/plastic small bags

- 0/1.2/1.25/1.35MT Big Bags

- Small bags inside big bags

- Big bags / small bags on pallet

- In bulk

- According to the customers’ detail requirements

The composition of white fused alumina is mainly industrial alumina powder, its main chemical composition is aluminium trioxide (Al2O3), with a content of more than 98%.

Support customization, you can leave your messages on the Message Board. We will contact you within 24 hours.

The hardness of white fused alumina is very high, the Mohs hardness is 9.0

Scratches appear in the polishing process because there are large grains in the abrasive product, resulting in a poor product appearance and poor cleanliness.

Yes, our factory’s micro powder has undergone acid and alkali washing, low impurity content, moisture precipitation process, and special electric furnace drying, so it has good cleanliness, uniform particle size and good particle shape.

We have professional standard national standard particle size comparison table, which can help you to standardise the model. Secondly, you can also send us a sample, our factory has professional testing instruments to help you analyse and accurately standardize the particle size of the products you use.