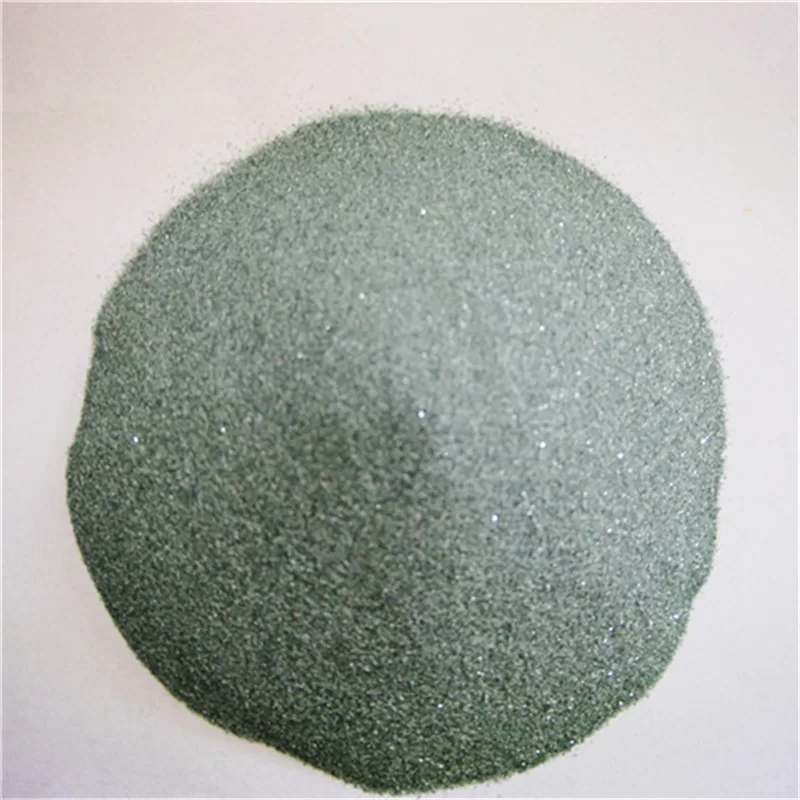

Green Silicon Carbide Powder

Green Silicon Carbide Powder

| Color | Green |

| Raw Material | Quartz Sand, Petroleum Coke (or Coal Coke), Sawdust |

| Crystal Structure | Hexagonal Crystal |

| True Density | 3.2 g/cm³ |

| Molecular Weight | 40.096 |

| Hardness (Mohs) | 9.5 |

| Melting Point | 2700°C |

| Particle Size | F Grit, P Grit, W Micro Powder, Segment Sand, Fine Powder |

| Applications | Refractory materials, abrasives, photovoltaic industry, semiconductor industry, piezoelectric crystals, and various other fields |

Green Silicon Carbide Micropowder Introduction:

Green silicon carbide micro powder is a micropowder material prepared from carbon and silicon raw materials. Its main component is Silicon Carbide (SiC) with chemical formula SiC.Green Silicon Carbide Micropowder usually has the characteristics of fine particle size, uniform particle size and green colour. It has high hardness, strong cutting ability, stable chemical properties, corrosion resistance and good thermal conductivity. Its microscopic shape is hexagonal crystal, and its Mohs hardness is 9.2 In the production process, it is usually graded by JZF grading equipment to meet the requirements of foreign and domestic products.

The grading requirement of silicon carbide micropowder is that no large particles can appear in the micropowder. The preparation of green silicon carbide micropowder is mainly based on petroleum coke and silica as raw materials, with table salt as an additive, and smelted at high temperature through resistance furnace. Overall, green silicon carbide powder has physical and chemical properties and is widely used in various fields.

| Test Products | SIC% | F.C% | Fe2O3% |

|---|---|---|---|

| Green silicon carbide 20#-90# | ≥99 | ≦0.20 | ≦0.20 |

| Green silicon carbide 100#-180# | ≥98.5 | ≦0.25 | ≦0.50 |

| Green silicon carbide 220#-240# | ≥98 | ≦0.25 | ≦0.70 |

Green silicon carbide powder has the following characteristics:

1. High hardness: the hardness of green silicon carbide powder is only second to that of diamond, so it has excellent abrasion and wear properties.

2. High strength: Green SIC powder has high flexural and compressive strength, which makes it an excellent structural material.

3. High-temperature performance: Green SIC powder can maintain stability at high temperatures, so it is widely used in high-temperature environments.

4. Corrosion resistance: green silicon carbide powder has good corrosion resistance to acid, alkali and other chemicals at room temperature.

Green silicon carbide powder has a wide range of applications, including but not limited to the following areas:

1. abrasive materials: green silicon carbide micropowder is used as the main component of abrasive materials such as sandpaper, grinding wheels and abrasive stones, which have long service life and fast grinding effect due to its high hardness and abrasive resistance.

2. Refractory materials: green silicon carbide powder can be used in the manufacture of refractory bricks, refractory coatings and refractory ceramics and other high-temperature materials, which are widely used in high-temperature industrial fields, such as thermal power plants, iron and steel smelting and cement manufacturing.

3. electronic materials: due to its high thermal conductivity and high temperature performance, green SIC powder is used to prepare high power semiconductor devices, electronic substrates and packaging materials.

4. photovoltaic materials: green SIC powder is often used in the manufacture of solar cell wafers as a dielectric or conductive layer to improve the efficiency of solar cells.

5. Other fields: Green SIC powders are also widely used in ceramic materials, coatings, corrosion-resistant coatings, chemical catalysts and reinforcing materials.

Packing:

- 25kg paper/plastic small bags

- 1.0/1.2/1.25/1.35MT Big Bags

- Small bags inside big bags

- Big bags / small bags on pallet

- In bulk

- According to the customers’ detail requirements

The composition of white corundum is mainly industrial alumina powder, its main chemical composition is aluminium trioxide (Al2O3), with a content of more than 98%.

Support customisation, you can leave your demand on the left side form. We will contact you within 24 hours.

The hardness of white corundum is very high, the Mohs hardness is 9.0

Scratches appear in the polishing process because there are large grains in the abrasive product, resulting in a poor product appearance and poor cleanliness.

是的,我厂微粉经过酸碱洗清洁度杂质含量少、水分沉淀工艺、专号专用电炉烘干,清洁度好、粒度均匀、颗粒形状好。

We have professional standard national standard particle size comparison table, which can help you to standardise the model. Secondly, you can also send us a sample, our factory has professional testing instruments to help you analyse and accurately standardize the particle size of the products you use.