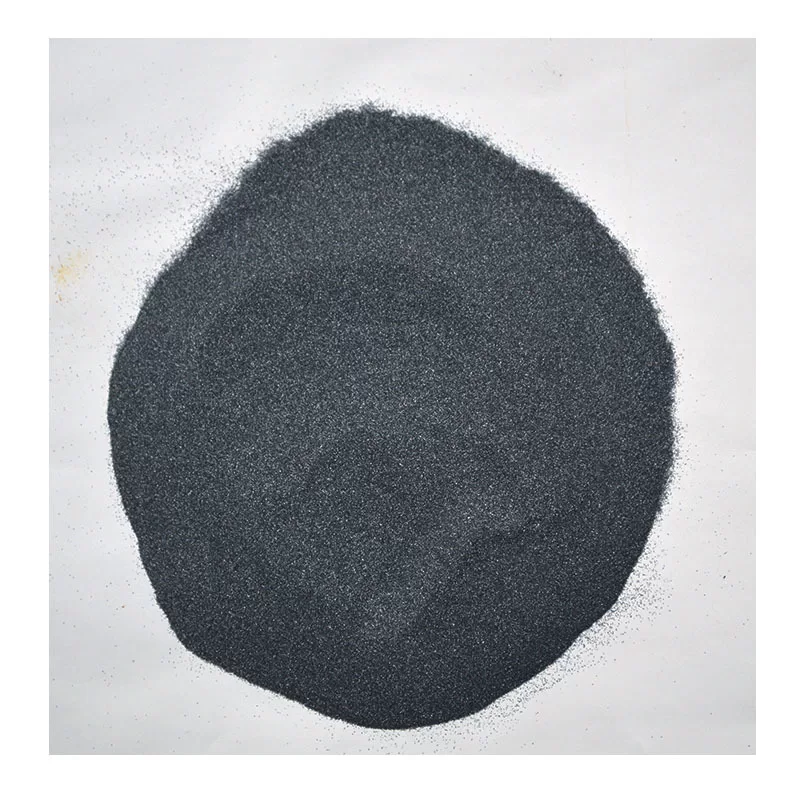

Black Fusde Alumina Granularity Sand

Black Fusde Alumina granularity sand

| Color | Black |

| Color System | Alpha-alumina trigonal system |

| Mohs Hardness | ≥9.0 |

| Melting Temperature(℃) | 2050℃ |

| Refractory Temperature(℃) | 1850℃ |

| True Density( g/cm3) | ≥3.50 |

| Expansion coefficient (0-1600℃) | 7-9 |

| Particle Size | F Grit, P Grit, W Micro Powder, Segment Sand, Fine Powder |

| Applications | Surface Processing, Beautification Processing, Etching Processing, Pre-treatment Processing, Deburring Processing, Stress Relief Processing |

Product Overview:

Black fused alumina is a highly durable and versatile abrasive with a wide range of applications across industries. Its unique combination of physical and chemical properties makes it suitable for sandblasting, surface preparation, polishing, refractory, and anti-skid flooring applications. Its high durability, low dust generation, versatility, and cost-effectiveness make it ideal for industrial processes.

Advantages:

Black fused alumina has a high hardness rating of 9 on the Mohs hardness scale, making it a suitable material for grinding and polishing hard surfaces. At the same time, the material exhibits excellent toughness, which allows it to withstand high impact and pressure without breaking.

Black Fused Alumina Abrasive sizes:

Refractory materials sizes: 0-1, 1-3, 3-5, 5-8 mm, 100, 200, 325 mesh

Abrasives sizes: 12, 14, 16, 24, 30, 36, 46, 60, 80, 100, 120, 150, 180, 200, 220, 240, 280, 325 mesh.

Micro powders for polishing and grinding: 400, 600, 800, 1000, 1500, 2000, 3000 mesh

Or as per specific requirements

Application:

1.Sandblasting

Black fused alumina is a commonly used abrasive for sandblasting. Its high hardness and toughness make it effective in removing rust, paint, and other surface coatings from metal surfaces. It is also used for surface preparation prior to painting or coating, as it creates a rough surface that promotes adhesion.

2.Surface Treatment

In addition to sandblasting, black fused alumina is also used for surface treatment in various industries. It is used for roughening and cleaning the surfaces of different materials, including metals, ceramics, and composites. Surface treatment with black corundum improves the adhesion and bonding of subsequent coatings, such as paints and sealants.

3.Polishing and Grinding

Black fused alumina is also used as an abrasive for polishing and grinding applications. Its high hardness and uniform particle size make it effective in achieving a smooth and uniform surface finish on metals, glass, and ceramics. It is commonly used in the production of optical lenses, electronic components, and precision parts.

4.Refractory Materials

Black fused alumina is a refractory material with excellent high temperature stability and chemical resistance. It is used in the production of refractory materials such as bricks, castables, and monolithic refractory materials. These materials are used in the construction of furnaces, kilns, and other high temperature applications.

5.Anti-slip flooring

Black fused alumina is also used to produce anti-slip flooring materials. Its high hardness and durability make it an ideal material for creating anti-slip surfaces in a variety of applications, including industrial floors, stairs, and walkways.

Packing:

- 25kg paper/plastic small bags

- 1.0/1.2/1.25/1.35MT Big Bags

- Small bags inside big bags

- Big bags / small bags on pallet

- In bulk

- According to the customers’ detail requirements

Support customisation, you can leave your demand on the left side form. We will contact you within 24 hours.

While both are alumina-based abrasives, Black Fused Alumina is tougher, less friable, and more heat resistant than White Fused Alumina. White Fused Alumina, on the other hand, is purer and has a higher hardness, making it better suited for precision applications and high-quality surface finishes.

White fused alumina (WFA), brown fused alumina (BFA), and black fused alumina (BLFA) are all types of fused alumina, which is a type of abrasive material made by melting alumina (Al2O3) and then solidifying it into blocks or grains.

The main difference between these three types of fused alumina is their color, which is a result of differences in the manufacturing process and the impurities present in the raw materials used.

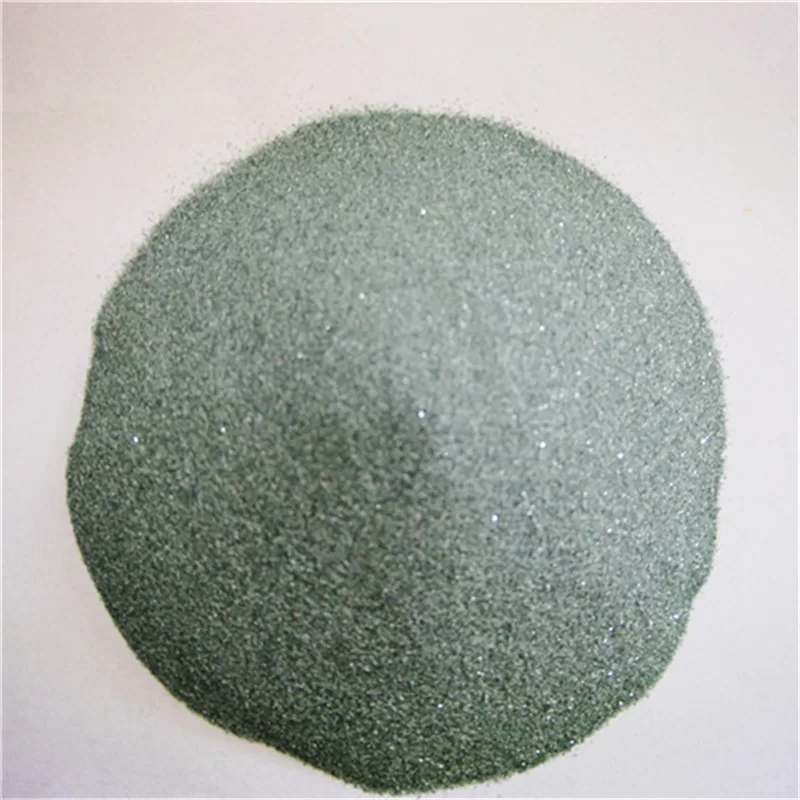

White fused alumina is made from high-quality alumina powder and is the purest form of fused alumina, with a white color and high hardness. It is commonly used in applications where a high level of purity is required, such as in the production of semiconductor wafers, precision casting, and high-end abrasives.

Brown fused alumina is made from bauxite, iron filings, and anthracite coal, and has a brown color. It has a lower purity than white fused alumina but is tougher and more durable, making it suitable for applications such as grinding and cutting.

Black fused alumina is made from bauxite and iron filings and has a black color. It is less pure than both white and brown fused alumina and is typically used in applications such as sandblasting, polishing, and surface preparation.

To choose the right silicon carbide abrasive, consider factors like the material being worked on, the desired finish, the abrasive life, and the equipment being used. Generally, harder materials require finer grits, while softer materials can be worked with coarser grits.