The difference between emery and white corundum

Diamond and white corundum, although both are hard materials, have significant differences in composition, properties

What kind of abrasive is used for sand blasting?

(1) The screen is not the same, plus one with 200 mesh screen, one with 325 mesh screen, the rate of screen is usually over 90

(2) Through the instrument detection, particle size analysis to determine the median value

F is the specification for cemented abrasives and sand blasting, which is more rounded in shape, while P is the specification for coated abrasives, which is usually presented as a sharp and rigid angular shape of the particles.

Yes, our brown corundum micropowder is made of first grade sand after acid and alkali washing + moisture overflow.

Yes, first grade material, high pile density 1.8 or more, more durable.

Each bag has 20kg and 25kg packaging, according to customer demand, are double-layer pouches.

Our factory produces granular sand with 16-220 mesh, complete models for you to choose.

Fine powder is mixed sand, there are many models in it, and micro powder is pure grain size number. Micro powder is washed by acid and alkali, no impurities, cleanliness will be higher, fine powder is not washed by acid and alkali, it is directly ground by mill.

White corundum micro powder is generally used in the field of oil stone, grinding wheel, cutting disc, fine grinding and so on.

Yes, provide the model you need and we will arrange to send you a sample.

Besides the different colour, green silicon carbide is a bit harder than black silicon carbide. The silicon carbide micropowders produced in our factory are all high-end abrasive grade, after acid and alkali washing + moisture overflow process, high cleanliness, no impurities, uniform particle size.

The main smelting methods of white corundum are dump furnace smelting and fixed furnace smelting. Both smelting methods are essentially the process of electrofusion recrystallisation of white corundum, but different processes will result in different characteristics. In practical application, you can choose the appropriate smelting method according to the specific needs and conditions.

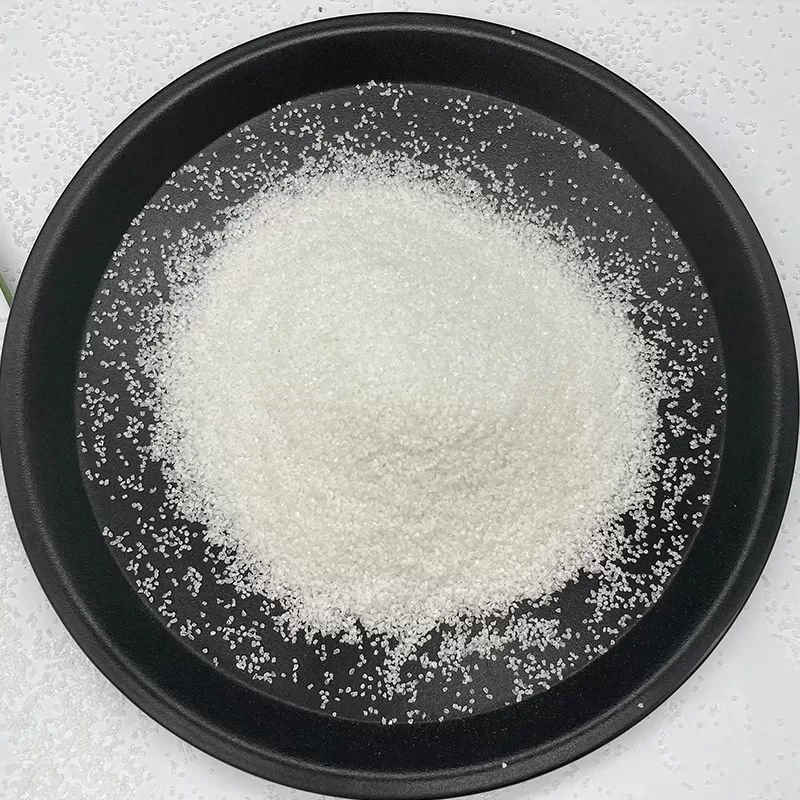

The composition of white corundum is mainly industrial alumina powder, its main chemical composition is aluminium trioxide (Al2O3), with a content of more than 98%.

Support customisation, you can leave your demand on the left side form. We will contact you within 24 hours.

The hardness of white corundum is very high, the Mohs hardness is 9.0

Scratches appear in the polishing process because there are large grains in the abrasive product, resulting in a poor product appearance and poor cleanliness.

是的,我厂微粉经过酸碱洗清洁度杂质含量少、水分沉淀工艺、专号专用电炉烘干,清洁度好、粒度均匀、颗粒形状好。

We have professional standard national standard particle size comparison table, which can help you to standardise the model. Secondly, you can also send us a sample, our factory has professional testing instruments to help you analyse and accurately standardize the particle size of the products you use.

There are basically two kinds of rhombic or pointed flake, usually related to the production process, different mills produce different particle shapes.

High hardness, less impurities, high content, high pile density of 1.83 or more, fixed furnace process.

What kind of abrasive is used for sand blasting?

(1) The screen is not the same, plus one with 200 mesh screen, one with 325 mesh screen, the rate of screen is usually over 90

(2) Through the instrument detection, particle size analysis to determine the median value

F is the specification for cemented abrasives and sand blasting, which is more rounded in shape, while P is the specification for coated abrasives, which is usually presented as a sharp and rigid angular shape of the particles.

Yes, our brown corundum micropowder is made of first grade sand after acid and alkali washing + moisture overflow.

Yes, first grade material, high pile density 1.8 or more, more durable.

Each bag has 20kg and 25kg packaging, according to customer demand, are double-layer pouches.

Our factory produces granular sand with 16-220 mesh, complete models for you to choose.

Fine powder is mixed sand, there are many models in it, and micro powder is pure grain size number. Micro powder is washed by acid and alkali, no impurities, cleanliness will be higher, fine powder is not washed by acid and alkali, it is directly ground by mill.

White corundum micro powder is generally used in the field of oil stone, grinding wheel, cutting disc, fine grinding and so on.

Yes, provide the model you need and we will arrange to send you a sample.

Besides the different colour, green silicon carbide is a bit harder than black silicon carbide. The silicon carbide micropowders produced in our factory are all high-end abrasive grade, after acid and alkali washing + moisture overflow process, high cleanliness, no impurities, uniform particle size.

The main smelting methods of white corundum are dump furnace smelting and fixed furnace smelting. Both smelting methods are essentially the process of electrofusion recrystallisation of white corundum, but different processes will result in different characteristics. In practical application, you can choose the appropriate smelting method according to the specific needs and conditions.

The composition of white corundum is mainly industrial alumina powder, its main chemical composition is aluminium trioxide (Al2O3), with a content of more than 98%.

Support customisation, you can leave your demand on the left side form. We will contact you within 24 hours.

The hardness of white corundum is very high, the Mohs hardness is 9.0

Scratches appear in the polishing process because there are large grains in the abrasive product, resulting in a poor product appearance and poor cleanliness.

是的,我厂微粉经过酸碱洗清洁度杂质含量少、水分沉淀工艺、专号专用电炉烘干,清洁度好、粒度均匀、颗粒形状好。

We have professional standard national standard particle size comparison table, which can help you to standardise the model. Secondly, you can also send us a sample, our factory has professional testing instruments to help you analyse and accurately standardize the particle size of the products you use.

There are basically two kinds of rhombic or pointed flake, usually related to the production process, different mills produce different particle shapes.

High hardness, less impurities, high content, high pile density of 1.83 or more, fixed furnace process.

Diamond and white corundum, although both are hard materials, have significant differences in composition, properties

The core advantage of this castable is its high temperature stability and excellent refractory performance.

The choice of abrasives and grinding agents is crucial in industrial production and processing. As

In the abrasive industry, white corundum is a very common material, but when it comes

Copyright 2018-2024 © All ymcorundum.com