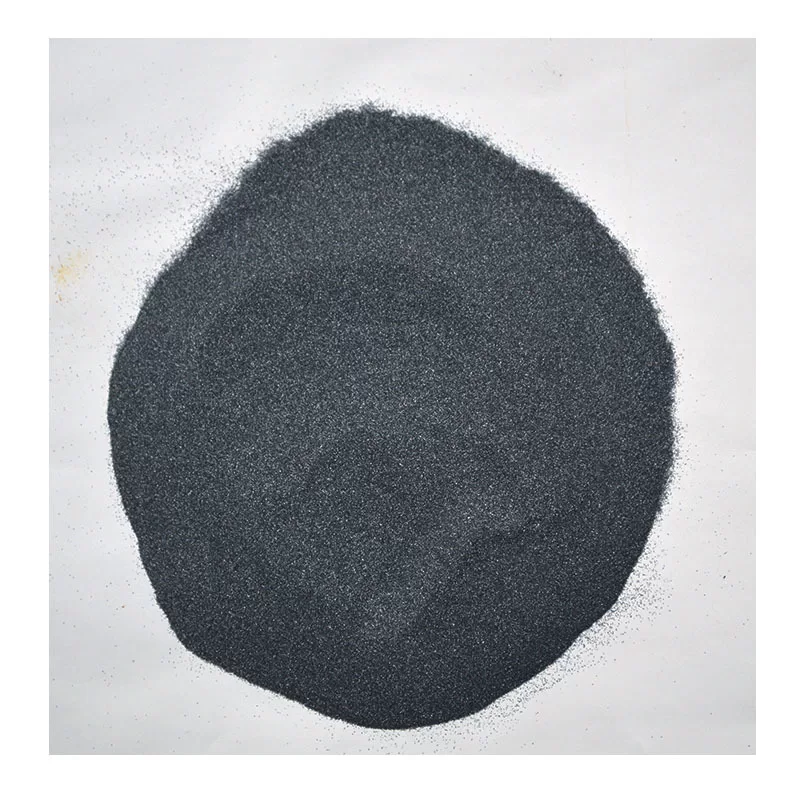

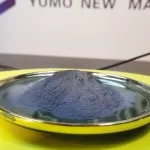

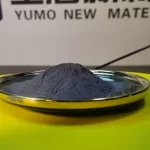

黒いシリコン炭化物パウダー

黒いシリコン炭化物パウダー

| 色 | 黒 |

| 原材料 | 石英砂, 石油コークス (またはコールコークス), おがくず |

| 結晶構造 | 六方晶系の結晶 |

| 真の密度 | 3.2 g/cm3 |

| 分子量 | 40.096 |

| 硬度 (モース) | 9.5 |

| 融点 | 2700℃ |

| 粒子サイズ | Fグリット, Pグリット, Wマイクロパウダー, セグメントサンド, 微粉 |

| アプリケーション | 金属加工, ガラス加工, セラミックス加工, エレクトロニクス, その他さまざまな分野 |

黒色炭化ケイ素微粉末の紹介:

黒色炭化ケイ素マイクロパウダーは、炭化ケイ素粒子を粉砕して作られた微粒子物質です。. 化学式はSiCです, 重要な無機材料です. 黒色炭化ケイ素微粉末は珪砂から作られています, 石油コークス (または石炭コークス), 木材チップなどの原料を抵抗炉で高温精錬する, 酸、アルカリ洗浄、その他の化学処理後, そして粉砕の中で, 再度ふるいにかけられる小さな粒子や粉末に到達するためのふるい分けおよびその他のプロセス, 微粒子の要件に沿った黒色炭化ケイ素の処理、再び水圧オーバーフローグレーディングプロセスまたはサイフォングレーディングプロセス, プロセスとは異なります, 黒色炭化ケイ素微粉末粒子を製造するための水洗工程のプロセスにより、収率と粒子の細かさが異なります。, 炭化ケイ素微粉末の組成は主に次のとおりです。: 炭化ケイ素, 三酸化鉄, 炭素, シリコン, 二酸化ケイ素, アルミニウム, PH, 導電性およびその他の内容. 炭化ケイ素は非常に硬いので、, 熱伝導性に優れています, 半導体の一種です, 高温でも酸素を失いません.

| テスト製品 | sic% | F.C% | fe2o3% |

|---|---|---|---|

| 黒色炭化ケイ素 12#-90# | ≥98.5 | ≦0.30 | ≦0.60 |

| 黒色炭化ケイ素 100#-180# | ≥98 | ≦0.30 | ≦0.80 |

| 黒色炭化ケイ素 220#-240# | 97以上 | ≦0.30 | ≦1.20 |

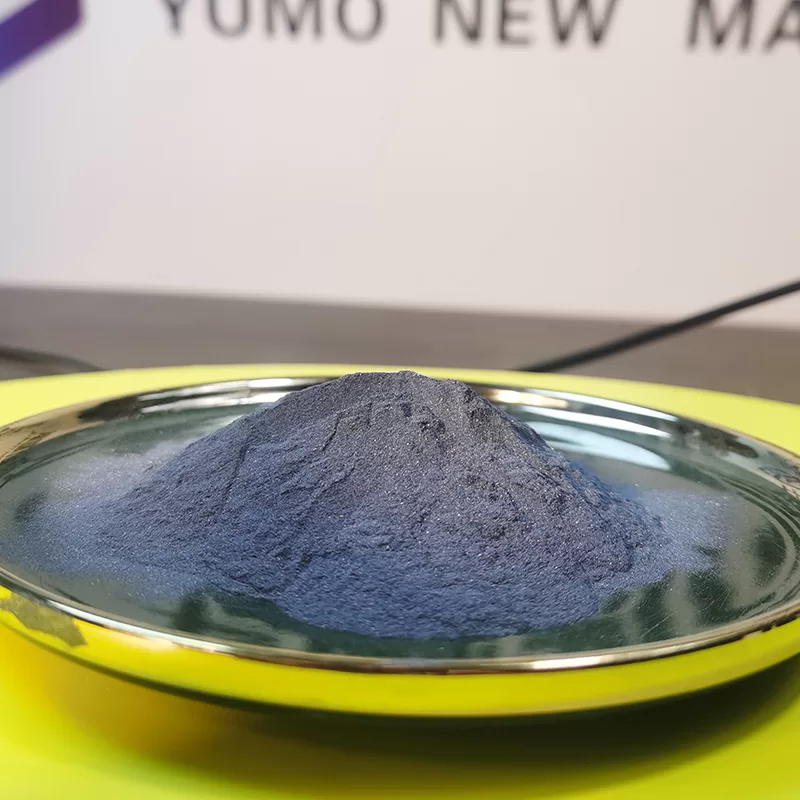

黒色炭化ケイ素微粉末の特徴:

1. 高硬度: 黒色炭化ケイ素微粉末の硬度はダイヤモンドに近く、ダイヤモンドに次ぐものです。. したがって, 優れた耐摩耗性があり、砥石の製造に使用できます。, サンドペーパーやその他の研磨剤.

2. 高温耐性: 黒色炭化ケイ素粉末は高温耐性があり、高温環境でも安定して動作します。.

3. 良好な熱伝導率: 黒色炭化ケイ素粉末は熱伝導率が高い, 放熱材料の製造に使用できます.

4. 耐食性: 黒色炭化ケイ素粉末は高い耐食性を持っています, 酸、アルカリ、その他のエッチング環境でも使用可能.

5. 高い破壊靱性: 黒色炭化ケイ素粉末は破壊靱性が高く、壊れにくい.

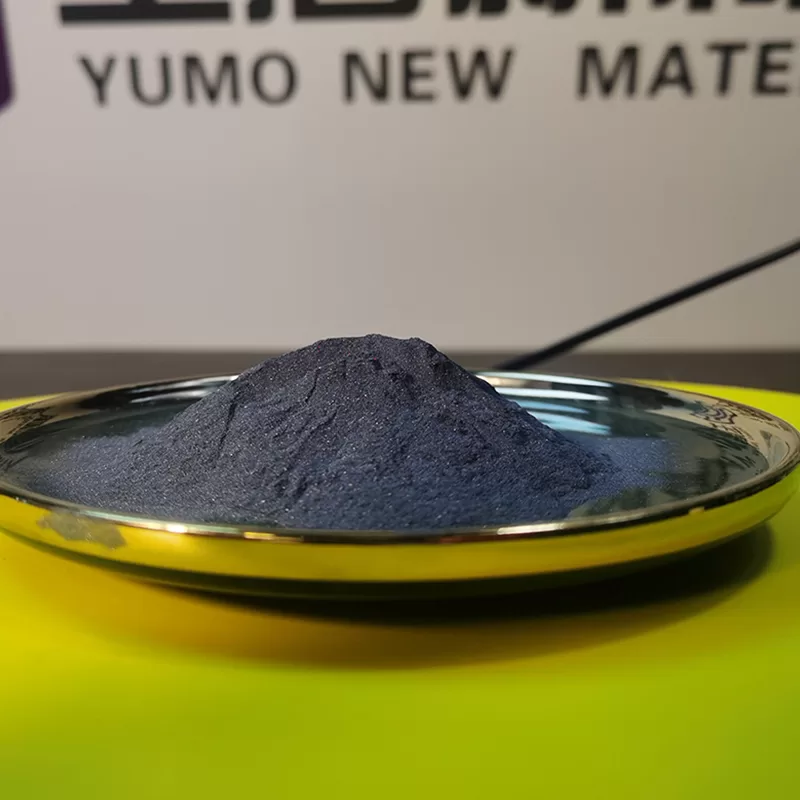

黒色炭化ケイ素微粉末の適用領域:

黒色炭化ケイ素微粉末は幅広い用途に使用できます. 研磨材の分野では, 金属加工の研磨材として使用できます。, ガラス加工, セラミック加工等. 陶磁器の分野では, 高温のセラミック材料を準備し、セラミック製品の硬度と使いやすさを向上させるために使用できます。. コーティング分野では, 黒色炭化ケイ素微粉末は、コーティングの使いやすさと耐食性を向上させるフィラーとして使用できます。. ゴムの分野では, 高強度ゴム製品の製造に使用できます. エレクトロニクス分野では, 黒色炭化ケイ素微粉末は、電子部品の放熱性能を向上させるための熱伝導性材料として使用できます。. 全体, 黒色炭化ケイ素微粉末は多くの分野で重要な応用価値を持っています.

パッキング:

- 25kg紙/プラスチック製の小さな袋

- 0/1.2/1.25/1.35マウントビッグバッグ

- 大きなバッグの中の小さな袋

- 大きなバッグ / パレットの小さな袋

- バルク

- 顧客の詳細要件によると

適切なシリコン炭化物研磨剤を選択します, 作業中の素材のような要因を考慮してください, 望ましい仕上げ, 研磨生活, 使用されている機器. 一般的に, より硬い材料には、より細かいグリッツが必要です, より柔らかい素材は、より粗いグリッツで動作することができます.

炭化ケイ素研磨材の粒度は粗いものから粗いものまであります。 (24 グリット) 極細まで (1200 グリット) さまざまな用途に使用されます, 素早い材料除去から精密研磨まで.

炭化ケイ素研磨剤は酸化アルミニウム研磨剤よりも硬く、鋭いです。, より攻撃的でより速い切断を可能にします. しかし, それらはさらに脆いです, 故障が早くなり、研磨剤の寿命が短くなる可能性があります.

サポートのカスタマイズ, 左側のフォームに要望を残すことができます. 以内にご連絡させていただきます 24 時間.