Our company implements very strict quality inspection and control in each major production process. We have a special inspection room with advanced inspection and testing equipment and professional inspection personnel, which can carry out quality inspection and testing according to the project requirements of metal coating in building manufacturing.

会社は顧客のニーズに応じてカスタマイズできます, 専門の標準粒子サイズの比較チャートとテスト機器を提供する, 顧客が製品のテストと評価を実施するように促進するためのサンプル配達サービスを提供する.

エナンユモNew Materials Co., 株式会社. の企業精神を遵守します “献身, 洗練, 厳密さと調和”, 卓越性を追求します, 強力なブランドイメージを確立します, 業界で良い評判を獲得しています.

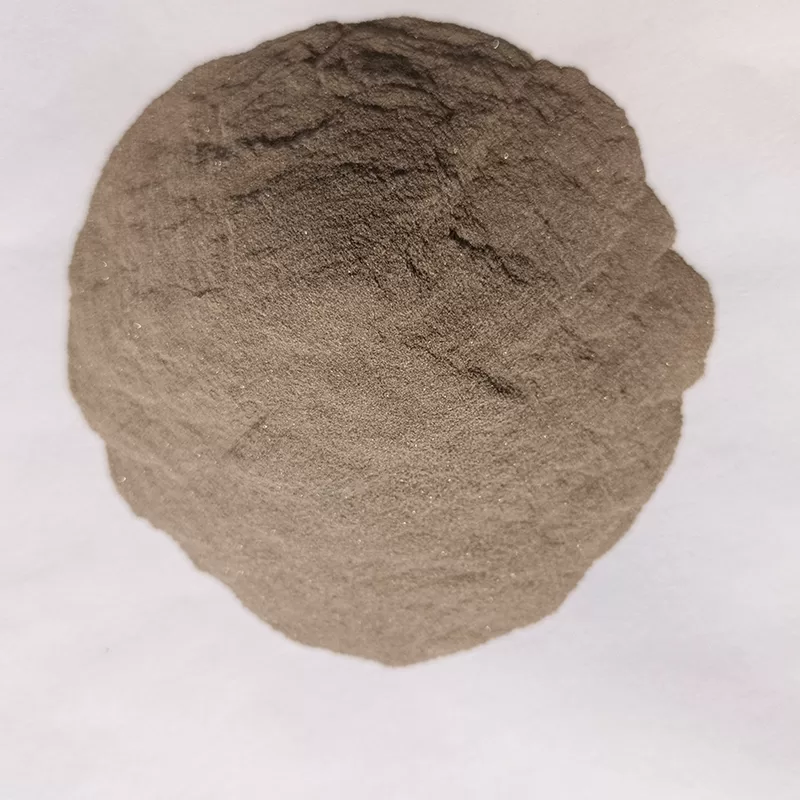

茶色の融合アルミナ, 褐色電融アルミナ (BFA) is made from Calcined Bauxite. It is a hard and tough material, used in manufacturing of grinding wheels (both vitrified and resin bonded) and coated products. These grains are also used for shot blasting and as polishing media. It is available in grit sizes as per FEPA for abrasive applications and group grits for refractory applications.

Brown Fused Alumina abrasives are mainly used for decontamination, derusting, anticorrosion, descaling, polishing and effect pattern of various materials.

一般的に言えば, there are three factors that affect the effect of sandblasting:

1. Grinding force: the higher the grinding force, the better the sand blasting effect.

2. Packing density: the higher the packing density, the better the sandblasting effect.

3. Dust: the lower the dust, the better the sand blasting effect.

Brown Fused Alumina dry cleaning sand with high packing density has a very good sandblasting effect.