What kind of abrasive is used for sand blasting?

(1) The screen is not the same, plus one with 200 mesh screen, one with 325 mesh screen, the rate of screen is usually over 90

(2) Through the instrument detection, particle size analysis to determine the median value

F is the specification for cemented abrasives and sand blasting, より丸みがあります, while P is the specification for coated abrasives, which is usually presented as a sharp and rigid angular shape of the particles.

はい, our brown corundum micropowder is made of first grade sand after acid and alkali washing + moisture overflow.

はい, first grade material, high pile density 1.8 or more, more durable.

Each bag has 20kg and 25kg packaging, according to customer demand, are double-layer pouches.

Our factory produces granular sand with 16-220 メッシュ, complete models for you to choose.

Fine powder is mixed sand, there are many models in it, and micro powder is pure grain size number. Micro powder is washed by acid and alkali, no impurities, cleanliness will be higher, fine powder is not washed by acid and alkali, it is directly ground by mill.

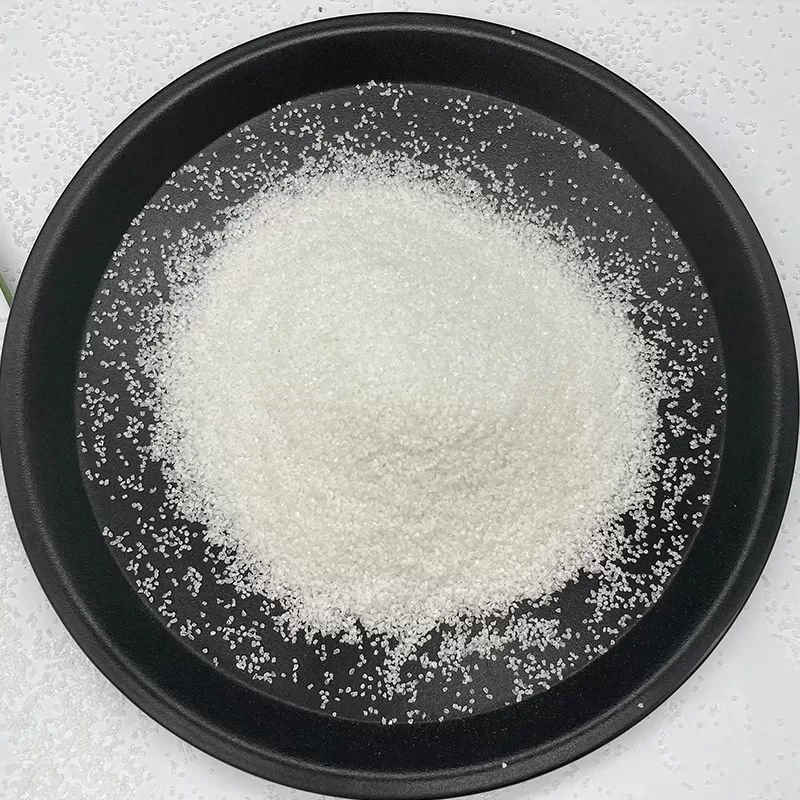

White corundum micro powder is generally used in the field of oil stone, grinding wheel, cutting disc, fine grinding and so on.

はい, provide the model you need and we will arrange to send you a sample.

Besides the different colour, green silicon carbide is a bit harder than black silicon carbide. The silicon carbide micropowders produced in our factory are all high-end abrasive grade, after acid and alkali washing + moisture overflow process, high cleanliness, no impurities, 均一な粒子サイズ.

The main smelting methods of white corundum are dump furnace smelting and fixed furnace smelting. Both smelting methods are essentially the process of electrofusion recrystallisation of white corundum, but different processes will result in different characteristics. In practical application, you can choose the appropriate smelting method according to the specific needs and conditions.

白色コランダムの組成は主に工業用アルミナ粉末です。, その主な化学組成は三酸化アルミニウムです (Al2O3), 以上の内容で 98%.

サポートのカスタマイズ, 左側のフォームに要望を残すことができます. 以内にご連絡させていただきます 24 時間.

白いコランダムは硬度が非常に高い, モース硬度は 9.0

砥粒に大きな粒子が含まれているため、研磨工程で傷が発生します。, 製品の外観が悪くなり、清浄度も低下します.

はい,当社工場のマイクロパウダーは、酸とアルカリで洗浄され、清潔で不純物含有量が低いことが保証されています。、水分沈殿プロセス、特殊電気炉乾燥,清潔感が良い、均一な粒子サイズ、良好な粒子形状。

専門標準の国家標準粒度比較表をご用意しております, モデルの標準化に役立ちます. 第二に, サンプルをお送りいただくこともできます, 私たちの工場には、使用する製品の粒子サイズを分析し、正確に標準化するのに役立つ専門的な検査機器があります。.

There are basically two kinds of rhombic or pointed flake, usually related to the production process, different mills produce different particle shapes.

高硬度, less impurities, 高いコンテンツ, high pile density of 1.83 or more, 炉のプロセスを固定しました.

What kind of abrasive is used for sand blasting?

(1) The screen is not the same, plus one with 200 mesh screen, one with 325 mesh screen, the rate of screen is usually over 90

(2) Through the instrument detection, particle size analysis to determine the median value

F is the specification for cemented abrasives and sand blasting, より丸みがあります, while P is the specification for coated abrasives, which is usually presented as a sharp and rigid angular shape of the particles.

はい, our brown corundum micropowder is made of first grade sand after acid and alkali washing + moisture overflow.

はい, first grade material, high pile density 1.8 or more, more durable.

Each bag has 20kg and 25kg packaging, according to customer demand, are double-layer pouches.

Our factory produces granular sand with 16-220 メッシュ, complete models for you to choose.

Fine powder is mixed sand, there are many models in it, and micro powder is pure grain size number. Micro powder is washed by acid and alkali, no impurities, cleanliness will be higher, fine powder is not washed by acid and alkali, it is directly ground by mill.

White corundum micro powder is generally used in the field of oil stone, grinding wheel, cutting disc, fine grinding and so on.

はい, provide the model you need and we will arrange to send you a sample.

Besides the different colour, green silicon carbide is a bit harder than black silicon carbide. The silicon carbide micropowders produced in our factory are all high-end abrasive grade, after acid and alkali washing + moisture overflow process, high cleanliness, no impurities, 均一な粒子サイズ.

The main smelting methods of white corundum are dump furnace smelting and fixed furnace smelting. Both smelting methods are essentially the process of electrofusion recrystallisation of white corundum, but different processes will result in different characteristics. In practical application, you can choose the appropriate smelting method according to the specific needs and conditions.

白色コランダムの組成は主に工業用アルミナ粉末です。, その主な化学組成は三酸化アルミニウムです (Al2O3), 以上の内容で 98%.

サポートのカスタマイズ, 左側のフォームに要望を残すことができます. 以内にご連絡させていただきます 24 時間.

白いコランダムは硬度が非常に高い, モース硬度は 9.0

砥粒に大きな粒子が含まれているため、研磨工程で傷が発生します。, 製品の外観が悪くなり、清浄度も低下します.

はい,当社工場のマイクロパウダーは、酸とアルカリで洗浄され、清潔で不純物含有量が低いことが保証されています。、水分沈殿プロセス、特殊電気炉乾燥,清潔感が良い、均一な粒子サイズ、良好な粒子形状。

専門標準の国家標準粒度比較表をご用意しております, モデルの標準化に役立ちます. 第二に, サンプルをお送りいただくこともできます, 私たちの工場には、使用する製品の粒子サイズを分析し、正確に標準化するのに役立つ専門的な検査機器があります。.

There are basically two kinds of rhombic or pointed flake, usually related to the production process, different mills produce different particle shapes.

高硬度, less impurities, 高いコンテンツ, high pile density of 1.83 or more, 炉のプロセスを固定しました.