河南裕莫新素材有限公司, 株式会社. 高品質の製品の生産を専門としています. 製品は、酸塩基洗浄と電気炉の乾燥プロセスを厳格にします, 高い純度を確保します, 均一な粒子サイズ, そして最小限の不純物.

会社は顧客のニーズに応じてカスタマイズできます, 専門の標準粒子サイズの比較チャートとテスト機器を提供する, 顧客が製品のテストと評価を実施するように促進するためのサンプル配達サービスを提供する.

エナンユモNew Materials Co., 株式会社. 「献身」の企業精神を遵守します, 洗練, 厳密さと調和」, 卓越性を追求します, 強力なブランドイメージを確立します, 業界で良い評判を獲得しています.

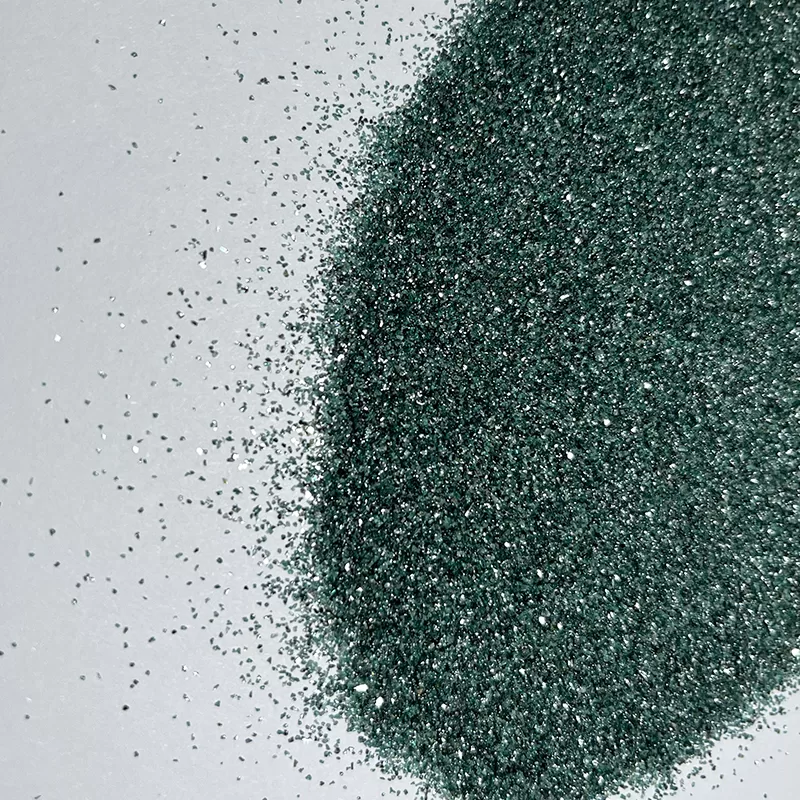

Green silicon carbide powder is a very hard abrasive with uniform particle size distribution. Its hardness is second only to diamond and B4C, and harder than black silicon carbide. したがって, it is suitable for grinding various hard materials such as titanium alloy, marble, hard alloy, 光学ガラス, セラミックス, 等. On the other hand, green silicon carbide has excellent characteristics such as high chemical stability and low thermal expansion rate, and is suitable for heat-resistant and corrosion-resistant coatings, paints, coatings and other building materials.

Characteristics of green silicon carbide micropowder:

1 Very high hardness (モース 9.5, Vickers 3100-3400kg/mm2 ), strong wear resistance.

2 Excellent chemical resistance and oxidation resistance.

3 High toughness.

4 Excellent thermal shock resistance, low coefficient of thermal expansion.

5 高温抵抗; high temperature strength.

6 Silicon carbide has high purity.

Application scenarios of green silicon carbide micropowder:

1. Precision polishing of hard optical glass such as camera lens.

2. Sand blasting and sharpening of hard metal CNB tools such as titanium alloy and hard alloy.

3. Polishing and grinding of quartz glass.

4 Grinding hard stone, marble, granite, 等.

5. Polishing PZT/piezoelectric ceramics.

6. Sandblasted copper, copper alloy, brass products, 等.

7. Surface treatment of diamond tools.

9. Grinding diamonds, cinnabar and other jewelry.

10. Grinding precision parts of other thin and brittle materials.

11. Fireproof new nano-airgel.

12. Fireproof insulation materials such as sintered ceramics.

13. Teflon coating (teflon non-stick pan coating added), fluorocarbon powder coating. It plays the role of wear resistance, corrosion resistance and high temperature resistance.

15. High-quality brake additives such as aviation aircraft brakes.

16. Silicon carbide ceramic filler.

17. Polishing tools such as diamond water grinding discs, PVC grinding discs, 等.