연마 산업에서, 흰색 커런덤은 매우 일반적인 재료입니다., but when it comes to white corundum fine powder, many people don’t know much about it. White corundum fine powder refers to white corundum mixed sand. White corundum fine powder has the characteristics of high purity, good self-sharpening, high hardness, slightly low toughness, and strong grinding power. 동시에, white corundum fine powder is mostly white, with low calorific value, 고효율, heat resistance, 좋은 열 안정성, 산과 알칼리 저항, 등.

The production process of white corundum fine powder mainly includes raw material screening, calcination, 눌러 터뜨리는, pulverization, screening, 자기 분리, packaging and other links. Calcination is the key step to improve the purity and density of white corundum, while crushing and pulverization are the process of processing raw materials into fine powder. In the crushing process, a crusher is used to break large pieces of raw materials into small pieces, and then the crusher is used to process them into fine powder. 동시에, in order to ensure the quality and purity of white corundum fine powder, screening and magnetic separation are also required.

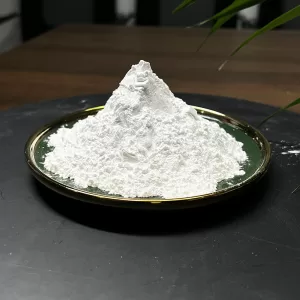

White corundum abrasive

White corundum fine powder has excellent physical properties, high hardness, high refractoriness and low thermal expansion coefficient. These advantages make white corundum fine powder widely used in many fields. For example, in the field of refractory materials, white corundum fine powder can be used to manufacture high-purity and high-density refractory products; in the field of abrasives and grinding tools, white corundum fine powder can be used to manufacture various abrasives and grinding tools, 그라인딩 휠과 같은, 사포, 등.; in the field of ceramic products, white corundum fine powder can be used to manufacture various high-precision and high-finish ceramic products; in the field of high-precision foundry sand, white corundum fine powder can be used to manufacture various high-precision and high-quality foundry sand. 동시에, it can also be customized according to the needs of different fields to meet the needs of different customers.