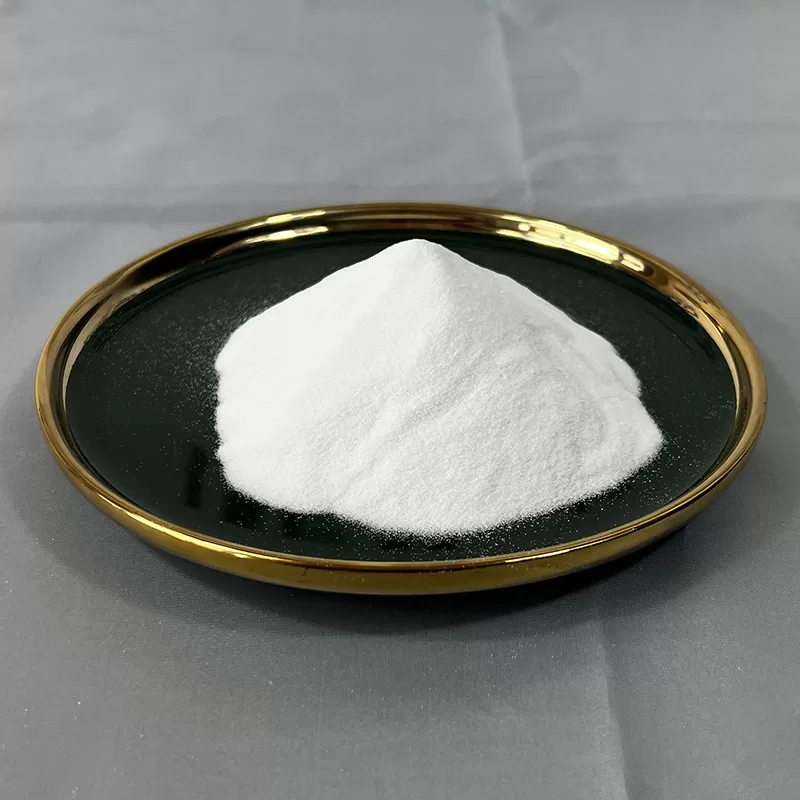

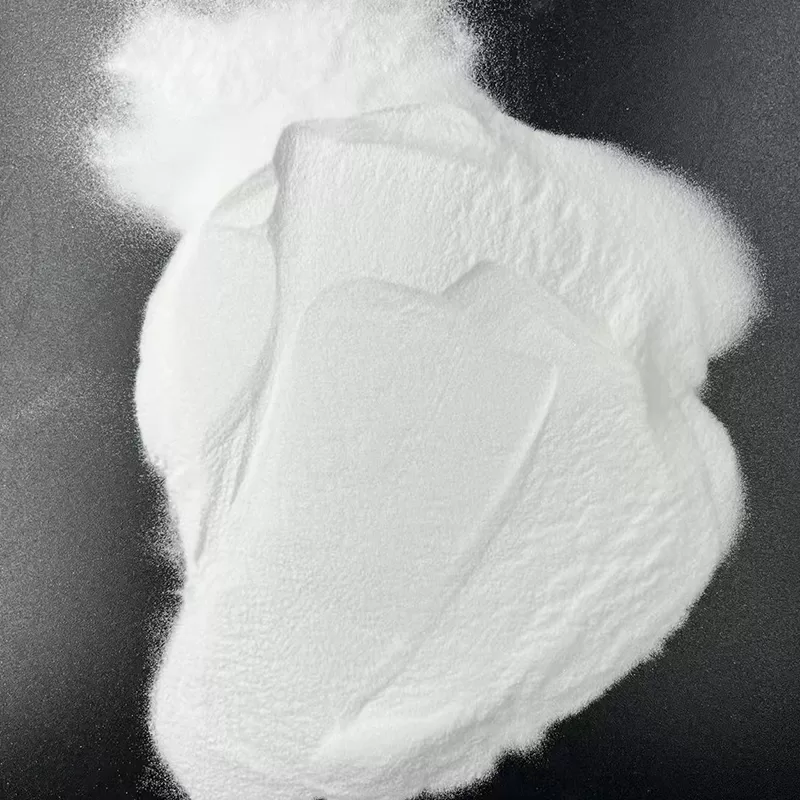

White fused alumina(WFA)

White fused alumina granularity size

| Color | White |

| Raw Material | Aluminium Oxide (Al2O3) |

| Crystal | Trigonal Crystal |

| True Density | 3.90 g/cm³ |

| Bulk Density | 3.60 g/cm³ |

| Hardness (Mohs) | 9 |

| Melting Point | 2250°C |

| Specific Heat (Cal/g·°C) | 0.26 (20 - 90°C) |

| Applications | Refractory industry, aerospace, automotive, electronics, chemical, construction materials, and precision manufacturing. |

Product Overview:

White Fused Alumina is electrically fused in arc furnace under the high temperature of above 2000°C with high grade processed alumina as raw material. It is divided into a variety of particle sizes after crushing, shaping, magnetic separation and iron removing. The WFA is dense texture, the hardness is slightly higher than that of Brown Fused Alumina, with high purity, good self-sharpness, strong grinding force, low calorific value, high efficiency, and acid and alkali corrosion resistance, good temperature stability, etc. White corundum abrasives are widely used in refractory materials, ceramic abrasive tools, resin abrasive tools, coated abrasive tools, grinding and polishing, sand blasting, precision casting and other fields.

Advantages:

The white fused alumina produced by our company has the advantages of high purity, strong self-sharpening, strong grinding force, high efficiency, high temperature resistance and corrosion stability. Abrasive tools made of it have the advantages of sharp grinding, low heat generation rate, high grinding efficiency, and little adhesion during use.

White Fused Alumina Abrasive sizes:

White Fused Alumina Abrasive sizes:F8 F10 F14 F16 F20 F24 F30 F36 F40 F46 F54 F60 F70 F80 F90 F100 F120 F150 F180 F220 Or as per specific requirements

| Test Products | Al2O3% | Na2O% | Fe2O3% | SIO2% | Magnetic Material(%) |

|---|---|---|---|---|---|

| White fused alumina F80 | ≥99.3 | ≦0.4 | ≦0.15 | – | ≦0.03 |

Application:

White Fused Alumina is used in many applications including grinding and cut off wheels, refractories and ceramic shapes, coated abrasives, investment casting shells, laminates, coatings, blasting abrasives, lapping and polishing, and many, many more.

1. Ceramic products, grinding and polishing, chamfering, etc.

2.Production of ceramic filter plates, foam ceramic filters, porous ceramics, water-absorbing ceramics, filter ceramics, honeycomb ceramics, ceramic membranes, polishing membranes, etc.

3.Rubber rollers/photoelectric industry/ceramics/diamond resin grinding wheels/wash basin surface coating fillers

4.Flooring, adhesives, electronic adhesives, FRP wear-resistant plates, FRP surface paint, gel coats, insulation board wear-resistant layers, etc.

5.Ceramic glazes, epoxy sand, UV coatings, wear-resistant floor coatings, environmentally friendly materials, powder coatings, environmentally friendly coatings, polyurethane coatings, PU coatings, anti-corrosion coatings, wear-resistant floor coating additives, etc.

6.Sandblasting, sandblasting by sandblasting machines, stainless steel sandblasting, semiconductor sandblasting, air conditioning equipment sandblasting, carbide sandblasting, nuclear engineering sandblasting, production of welding materials, silicon wafer sandblasting, P.C.B circuit board sandblasting, surface treatment, rust removal, mobile phone case sandblasting, kitchenware sandblasting, tungsten, molybdenum, titanium and other rare metal products, carbide sandblasting, etc.

Packing:

- 25kg paper/plastic small bags

- 1.0/1.2/1.25/1.35MT Big Bags

- Small bags inside big bags

- Big bags / small bags on pallet

- In bulk

- According to the customers’ detail requirements

The composition of white fused alumina is mainly industrial alumina powder, its main chemical composition is aluminium trioxide (Al2O3), with a content of more than 98%.

Customization is supported. You can leave your requirements on the message board and we will contact you within 24 hours.

The hardness of white corundum is very high, the Mohs hardness is 9.0

Fused alumina offers superior hardness, sharpness, and durability, resulting in efficient material removal, consistent surface finish, and extended abrasive life compared to other abrasives.

Yes, our factory’s micro powder has undergone acid and alkali washing, low impurity content, moisture precipitation process, and special electric furnace drying, so it has good cleanliness, uniform particle size and good particle shape.

Fused alumina with fine grain sizes and high purity levels can be used for polishing and finishing applications in industries such as optics, jewelry, and precision manufacturing to achieve smooth and reflective surfaces..