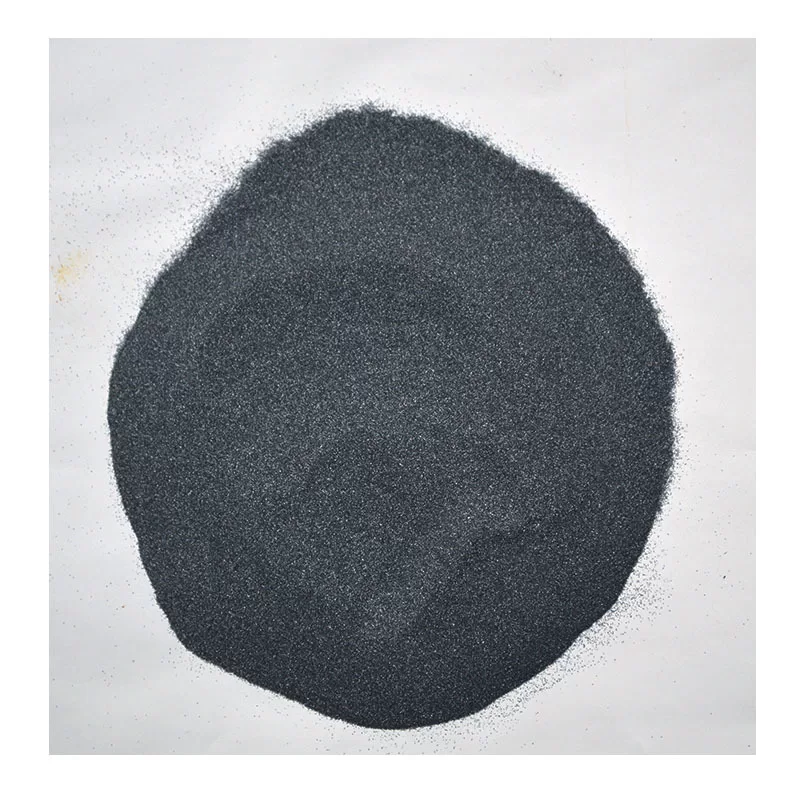

Black Fusde Alumina Granularity Sand

Black Fusde Alumina granularity sand

| 颜色 | 黑色的 |

| Color System | Alpha-alumina trigonal system |

| Mohs Hardness | ≥9.0 |

| Melting Temperature(℃) | 2050℃ |

| Refractory Temperature(℃) | 1850℃ |

| 真密度( 克/立方厘米) | ≥3.50 |

| Expansion coefficient (0-1600℃) | 7-9 |

| 粒径 | F 砂砾, 磷砂砾, W微粉, 段砂, 细粉 |

| 应用领域 | 表面处理, 美化处理, 蚀刻加工, 前处理加工, 去毛刺加工, 应力消除处理 |

产品概述:

Black fused alumina is a highly durable and versatile abrasive with a wide range of applications across industries. Its unique combination of physical and chemical properties makes it suitable for sandblasting, surface preparation, 抛光, refractory, and anti-skid flooring applications. Its high durability, low dust generation, versatility, and cost-effectiveness make it ideal for industrial processes.

优点:

Black fused alumina has a high hardness rating of 9 on the Mohs hardness scale, making it a suitable material for grinding and polishing hard surfaces. 同时, the material exhibits excellent toughness, which allows it to withstand high impact and pressure without breaking.

Black Fused Alumina Abrasive sizes:

Refractory materials sizes: 0-1, 1-3, 3-5, 5-8 mm, 100, 200, 325 网

Abrasives sizes: 12, 14, 16, 24, 30, 36, 46, 60, 80, 100, 120, 150, 180, 200, 220, 240, 280, 325 网.

Micro powders for polishing and grinding: 400, 600, 800, 1000, 1500, 2000, 3000 网

Or as per specific requirements

应用:

1.喷砂

Black fused alumina is a commonly used abrasive for sandblasting. Its high hardness and toughness make it effective in removing rust, 画, and other surface coatings from metal surfaces. It is also used for surface preparation prior to painting or coating, as it creates a rough surface that promotes adhesion.

2.表面处理

In addition to sandblasting, black fused alumina is also used for surface treatment in various industries. It is used for roughening and cleaning the surfaces of different materials, 包括金属, 陶瓷, and composites. Surface treatment with black corundum improves the adhesion and bonding of subsequent coatings, such as paints and sealants.

3.Polishing and Grinding

Black fused alumina is also used as an abrasive for polishing and grinding applications. Its high hardness and uniform particle size make it effective in achieving a smooth and uniform surface finish on metals, 玻璃, and ceramics. It is commonly used in the production of optical lenses, electronic components, and precision parts.

4.Refractory Materials

Black fused alumina is a refractory material with excellent high temperature stability and chemical resistance. It is used in the production of refractory materials such as bricks, 浇注料, and monolithic refractory materials. These materials are used in the construction of furnaces, 窑炉, and other high temperature applications.

5.Anti-slip flooring

Black fused alumina is also used to produce anti-slip flooring materials. Its high hardness and durability make it an ideal material for creating anti-slip surfaces in a variety of applications, including industrial floors, stairs, and walkways.

包装:

- 25公斤纸/塑料小袋

- 1.0/1.2/1.25/1.35MT 大袋

- 大袋子里面装着小袋子

- 大袋子 / 托盘上的小袋子

- 散装

- 根据客户的详细要求

支持定制, 您可以在左侧表格中留下您的需求. 我们将在以下时间内与您联系 24 小时.

While both are alumina-based abrasives, Black Fused Alumina is tougher, less friable, and more heat resistant than White Fused Alumina. 白刚玉, on the other hand, is purer and has a higher hardness, making it better suited for precision applications and high-quality surface finishes.

白刚玉 (世界足协), 棕刚玉 (博鳌亚洲论坛), and black fused alumina (BLFA) are all types of fused alumina, which is a type of abrasive material made by melting alumina (三氧化二铝) and then solidifying it into blocks or grains.

The main difference between these three types of fused alumina is their color, which is a result of differences in the manufacturing process and the impurities present in the raw materials used.

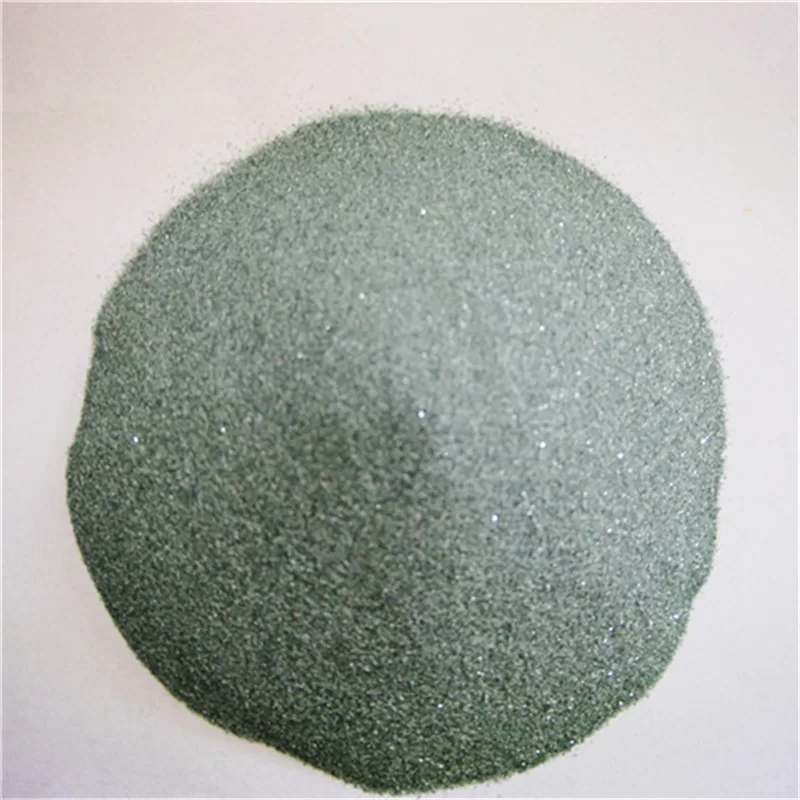

White fused alumina is made from high-quality alumina powder and is the purest form of fused alumina, with a white color and high hardness. It is commonly used in applications where a high level of purity is required, such as in the production of semiconductor wafers, precision casting, and high-end abrasives.

Brown fused alumina is made from bauxite, iron filings, and anthracite coal, and has a brown color. It has a lower purity than white fused alumina but is tougher and more durable, making it suitable for applications such as grinding and cutting.

Black fused alumina is made from bauxite and iron filings and has a black color. It is less pure than both white and brown fused alumina and is typically used in applications such as sandblasting, 抛光, and surface preparation.

选择合适的碳化硅磨料, 考虑诸如正在加工的材料等因素, 所需的完成, 磨料寿命, 以及正在使用的设备. 一般来说, 较硬的材料需要更细的粒度, 而较软的材料可以使用较粗的砂粒进行加工.