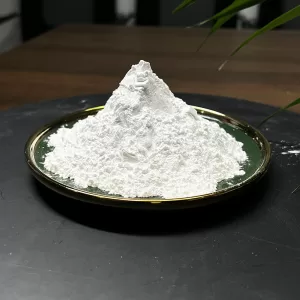

在磨料磨料行业, 白刚玉是一种很常见的材料, 但是,当涉及白色圆锥形细粉, 许多人对此不太了解. 白色圆锥形细粉是指白色圆锥形混合沙子. 白色圆锥形细粉具有高纯度的特征, 良好的自我份额, 高硬度, 韧性略低, 和强大的力量. 同时, 白色圆锥细粉主要是白色, 具有低热量, 高效率, 耐热性, 良好的热稳定性, 酸和碱性, ETC.

白色刚果粉的生产过程主要包括原材料筛选, 钙化, 压碎, 粉碎, 筛选, 磁选, 包装和其他链接. 钙化是提高白色圆锥的纯度和密度的关键步骤, 而压碎和粉碎是将原材料加工成细粉的过程. 在压碎过程中, 破碎机用于将大块的原材料分解成小块, 然后使用破碎机将它们加工成细粉. 同时, 为了确保白色圆锥形细粉的质量和纯度, 还需要筛选和磁分离.

白刚玉磨料

白色圆锥形细粉具有出色的物理特性, 高硬度, 高折射率和低热膨胀系数. 这些优势使白色刚果精细粉末广泛用于许多领域. 例如, 在难治材料领域, 白色圆锥形细粉可用于制造高纯度和高密度耐火产品; 在磨料和研磨工具领域, 白色圆锥形细粉可用于制造各种磨料和研磨工具, 比如砂轮, 砂纸, ETC。; 在陶瓷产品领域, 白色圆锥形细粉可用于制造各种高精度和高精细陶瓷产品; 在高精度铸造砂领域, 白色圆锥形细粉可用于制造各种高精度和高质量的铸造砂. 同时, 也可以根据不同领域的需求来定制它以满足不同客户的需求.