The industry standards for white corundum micropowder cover many aspects to ensure the stability of its quality, performance and application effect. Here are some of the main standards:

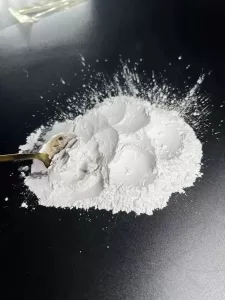

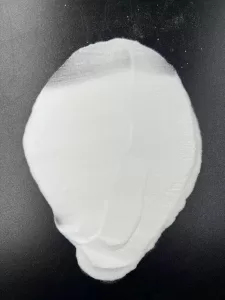

Appearance requirements: White corundum micropowder should be white powder, free of impurities, mechanical impurities, and coarse particles. This is a specification of its basic appearance to ensure the purity and consistency of the product.

Particle size distribution: The particle size distribution range should comply with the regulations, and the particle size distribution of sand of different specifications should meet the corresponding standard requirements. Particle size is a key factor in the performance and application effect of white corundum micropowder, so the standardization of its distribution range is very important.

Density and hardness: The density and hardness of white corundum micropowder are also important performance indicators. The density should not be lower than the standard value to ensure its tight structure and hard texture; the hardness is required to reach a specific level to meet the needs of different application scenarios.

White corundum micropowder

Impact resistance: White corundum micropowder is subjected to impact resistance test under specified conditions, and should not be broken or significantly deformed. This standard ensures the stability and durability of the micropowder during use.

Chemical composition: The chemical composition of white corundum powder should comply with regulations, with the main component being aluminum oxide, and should not contain substances harmful to the human body.

Packaging and storage: The packaging of the product should be made of packaging materials with good sealing, moisture-proof and humidity-proof to ensure that the product is not contaminated or deteriorated during transportation and storage. At the same time, the product name, specifications, production date, shelf life, manufacturer and other information should be indicated on the packaging for easy identification and management.

White corundum powder manufacturer

Testing rules: Each batch of white corundum powder products should be tested for appearance, particle size distribution, water content, heat resistance, corrosion resistance, etc., and the test results should be recorded. Products that fail the test shall not be used for production or sales, and should be reworked or scrapped. In addition, regular calibration and maintenance of production equipment and testing equipment are also important measures to ensure the accuracy and reliability of test results.

These industry standards are designed to ensure the quality and performance of white corundum powder and meet the application needs of various industries. The specific standard values may vary according to the standard-setting agencies in different regions, so it is necessary to refer to the corresponding industry standards or specifications in actual applications.