Our company implements very strict quality inspection and control in each major production process. We have a special inspection room with advanced inspection and testing equipment and professional inspection personnel, which can carry out quality inspection and testing according to the project requirements of metal coating in building manufacturing.

회사는 고객의 요구에 따라 사용자 정의 할 수 있습니다, 전문 표준 입자 크기 비교 차트 및 테스트 장비 제공, 고객이 제품 테스트 및 평가를 수행 할 수 있도록 샘플 배송 서비스를 제공합니다..

허난 유모 신소재 유한회사, 주식회사. 기업의 정신을 고수합니다 “봉납, 정제, 엄격하고 조화”, 우수성을 추구합니다, 강력한 브랜드 이미지를 설정합니다, 그리고 업계에서 좋은 명성을 얻었습니다.

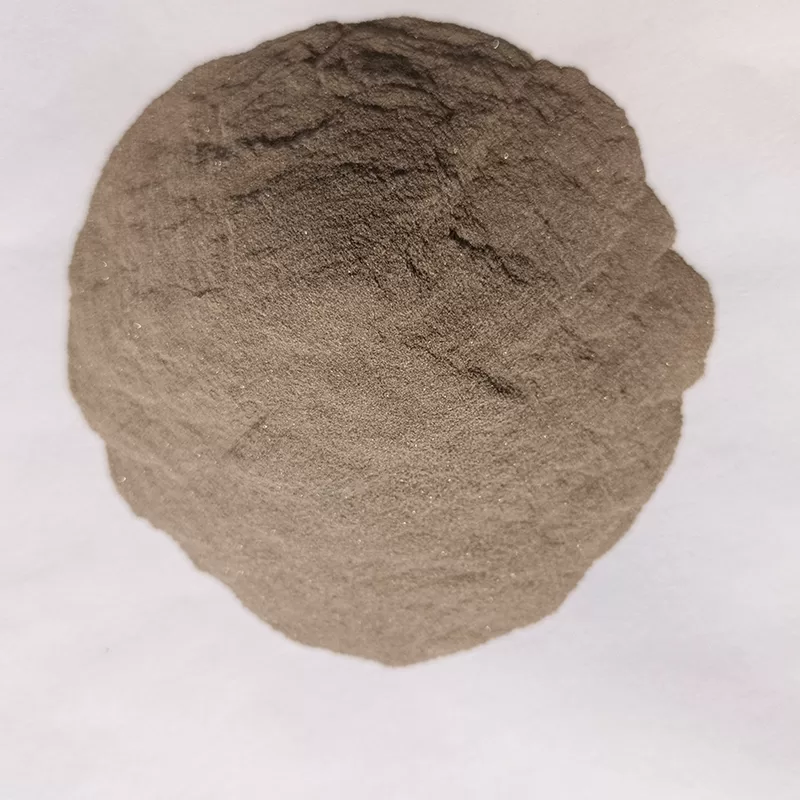

Brown fused alumina, 브라운 용융 알루미나 (BFA) is made from Calcined Bauxite. It is a hard and tough material, used in manufacturing of grinding wheels (both vitrified and resin bonded) and coated products. These grains are also used for shot blasting and as polishing media. It is available in grit sizes as per FEPA for abrasive applications and group grits for refractory applications.

Brown Fused Alumina abrasives are mainly used for decontamination, derusting, anticorrosion, descaling, polishing and effect pattern of various materials.

일반적으로 말하면, there are three factors that affect the effect of sandblasting:

1. Grinding force: the higher the grinding force, the better the sand blasting effect.

2. Packing density: the higher the packing density, the better the sandblasting effect.

3. Dust: the lower the dust, the better the sand blasting effect.

Brown Fused Alumina dry cleaning sand with high packing density has a very good sandblasting effect.